Whether you’re in search of roof drain specifications, product catalog, or anything in between, we have the resources to answer your questions.

As an industry professional, you need the right resources to help make your roof drain decisions. Browse our resource library below for expert knowledge on roof drain specs, parts, accessories, and more.

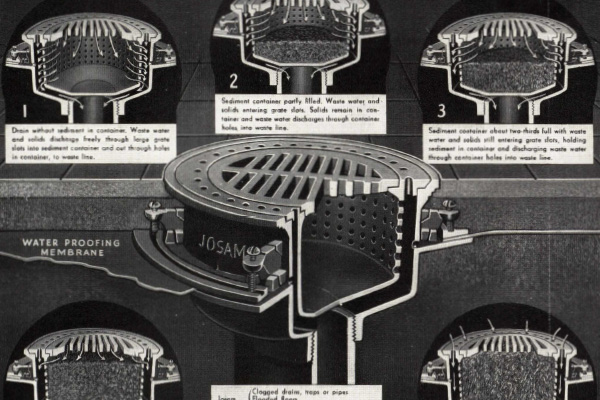

The Drain Library features a collection of articles, catalogs, and patents from well-known drain manufacturers across the U.S.

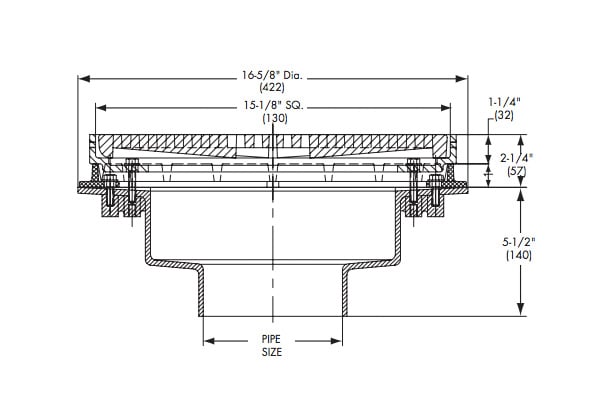

If you’re in need of roof drain specifications, take a look at these diagrams and dimensions from several top roof drain manufacturers.

Looking for a specific roof drain? Let the Drain Wizard help you find an option that matches your unique needs and price point.

We've built our business on more than 35 years of personal conversations and problem-solving with our customers. Our team is ready to assist you, so contact us today.

© 2024 Hy-Tech Products, Inc. All rights reserved. Terms of Use